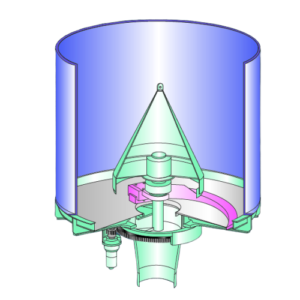

Silo Discharge Machine

The task of the central discharge unit silo discharge machine is to extract wet, cohesive, sluggish or other non free flowing bulk material stored or buffered in bins or silos. The rotating discharge arm conveys the bulk material toward the opening in the center of the floor and discharges it through this opening. To prevent the bulk material from flowing out in an uncontrolled manner, the discharge opening is covered by an inner cone. The discharge arm passes underneath the inner cone and activates the entire silo bottom during the discharge operation. One revolution of this specially curved and profiled arm extracts a uniform disc of material from the silo. This keeps the bulk material column in motion and maintains its flow ability, preventing solidification of the bulk material over time and the risk of bridge formation inside the silo.

Silo Discharge Machine has a diameter in the range of 1.5 and 5.0 m. Discharge capacity in the range of 350 to 500 TPH.

Silo discharge machine ensures a problem free silo discharge with continuous mass flow by avoiding bridging and/or funnel flow. This is achieved by way proper design of silo shapes in accordance with bulk material analysis.

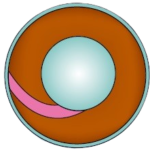

Inner Cone Supported on Bearings with External Drive

The free spinning cone has the advantage of having no obstacles such as cross beams or cone supports that would disrupt the material flow. Very sticky or non-free-flowing bulk materials have no chance to build bridges.

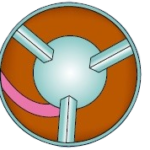

Inner Cone Supported on Support arms with External Drive

This design is used for bulk materials with poor flow characteristics, or for surge bins where long periods of storage time are not necessary.

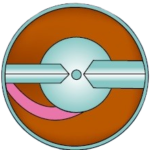

Internal Drive Machine

This feature gives you the advantage of storing very dusty bulk materials or materials that have the tendency for spontaneous combustion. One of the arms is built as an inspection tunnel, so maintenance can be done without emptying the silo.